Linmot Linear Motors

Whenever translational motions need to be performed dynamically, with low friction and high flexibility, users choose linear systems.The core of the LinMot drive system consists of the control electronics, the servo drive, and the linear motors.

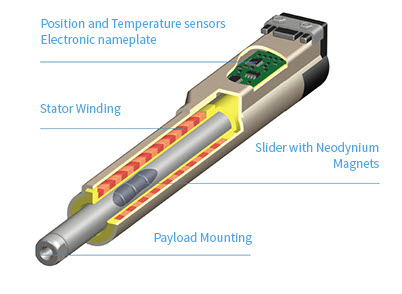

LinMot motors are electromagnetic direct drives in tubular form. The linear motion is produced purely electrically and wear-free, without any intermediate coupling of mechanical gearboxes, spindles, or belts. The linear motor consists of just two parts: the slider and the stator. The slider is made of neodymium magnets that are mounted in a high-precision stainless steel tube. The stator contains the motor windings, bearings for the slider, position capture sensors, and a microprocessor circuit for monitoring the motor.

The internal position sensor measures and monitors the current position of the linear motor not only when it is stopped, but also during the motion. Deviations in position are detected immediately and reported to the upper-level controller. LinMot linear motors can be positioned freely within the entire range of the stroke. In addition, both the travel speed and the acceleration can be controlled precisely. For more complex motions, arbitrary travel profiles can be saved as curves in the servo drive and executed by the motor at the desired speed.

The design of the linear motors makes them standard elements in the field of machine design, where they are commonly used to replace pneumatic drives and mechanical cam discs. With LinMot linear motors and simple guides, the engineer has all the components needed to design complete linear drive systems.

Standard Motors

The standard variant of the linear motor can be used universally, covering a wide range of applications. Many different positioning tasks in the low-voltage range can be performed using the compact drives. The family of motors includes 3 models with various lengths of the stator and the stroke. The user can select a maximum stroke length of 1830 mm and peak force of 1024 N. Because the motor components are encapsulated, the motor is optimally protected, even for intensive applications.

HP Motors

The High Performance line of linear motors have significantly greater performance than standard motors with the same component size and identical dimensions. This is largely due to the ongoing development of the motor windings and the magnetic circuit, and the use of high-performance materials.

With High Performance motors, the user has access to nearly double the nominal performance. The higher performance in the same form factor allows power to be increased in existing machines and systems without the trouble of mechanical redesign.

Short Motors

This type of motor is the shortest form factor for LinMot linear motors. Short motors have been developed especially for applications with limited space constraints. The short form factor also means that multi-axis applications can be implemented with several stators on one slider in a very small space. In order to provide the designer with as many options as possible for cable routing, these motors are provided with three covers for the cable outlet on the left, the right, or the front side. The motor cable can be plugged in under the cover for quick and easy installation.

Linear Motors 3x400VAC

The P10-70 series of motors are the most powerful drives that LinMot makes.

The larger motors with increased performance and more than three times the peak force present greater challenges for drive units and servo drives. Therefore, LinMot has developed an entirely new concept here, with a three-phase winding and servo drives that are fed directly from the grid.

The control electronics and the motor together provide an outstanding alternative to conventional design elements.

Series P10-70 linear motors are available with various encoder interfaces and can therefore be controlled by third-party servo drives without any difficulties. Series P10-70 linear motors have been tested together with the leading manufacturers of servo drives.